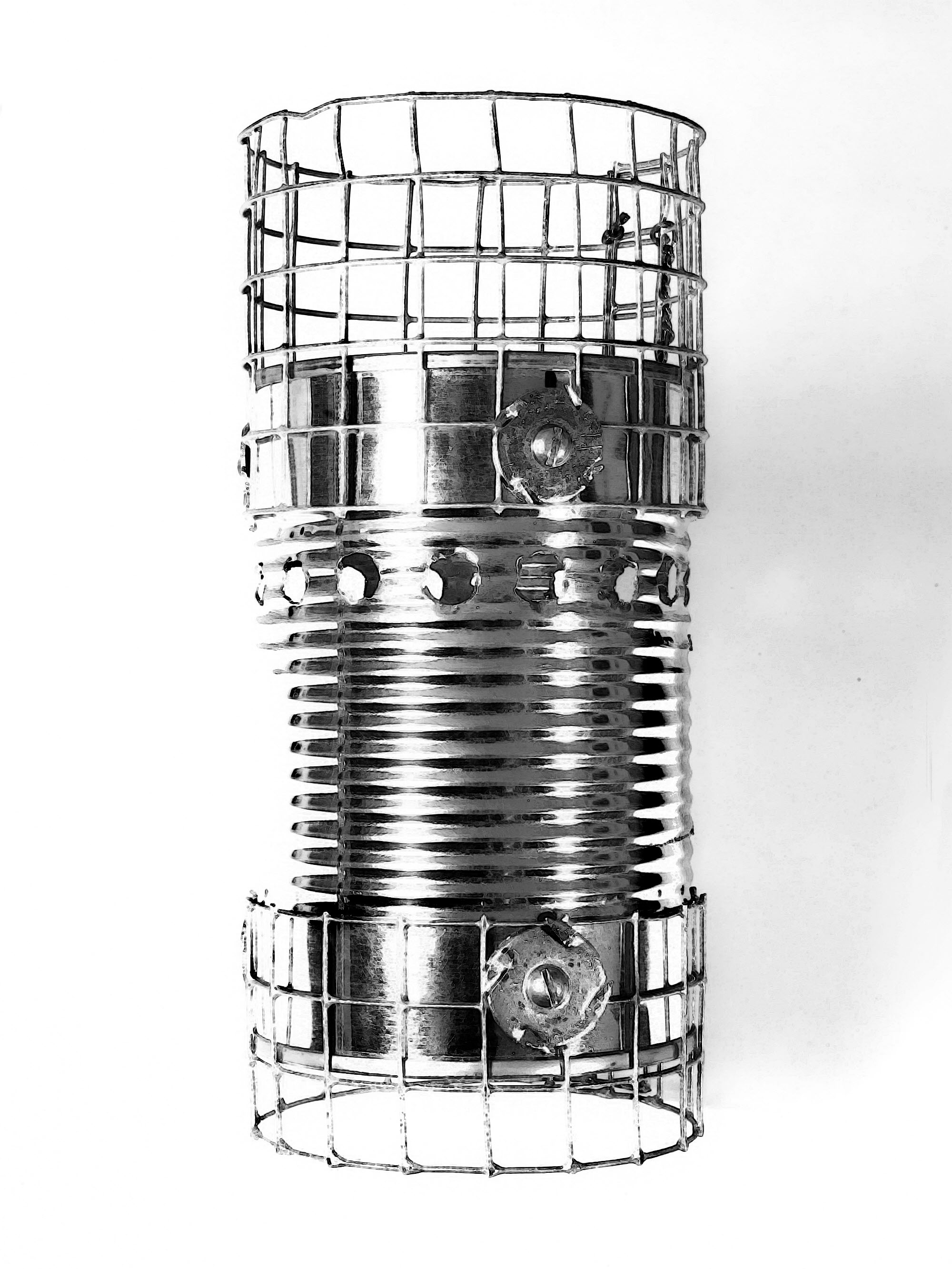

Scott Henderson's Pepsi-G Stove

Note from editor: I originally got interested in making my own stoves after reading Scott Henderson's instructions, first published in 2001.

Note from editor: I originally got interested in making my own stoves after reading Scott Henderson's instructions, first published in 2001.

In the years since then, those instructions have gone away, along with the site where they were published. But, I did manage to piece together the originals a couple of years back.

My comments are denoted by "Note from editor". The rest is the original, except that the formatting is different, and I've removed dead links.

If anyone owns this information and objects to it being published here, let me know. Otherwise share and enjoy.

STOVE PARTS

Aluminum cans in mint condition (no dents), one each of:

- 12 oz PepsiCo (Budweiser, Lipton's Ice Tea, Mountain Dew, Mug Root Beer, Pepsi, Sierra Mist, or Slice).

- 14.9 oz Guinness Draught, Caffrey's Irish Ale, or Murphy's Irish Stout.

- If you use a Murphy's can see Notes in STEP 5 for special instructions.

- If you substitute a 12 oz can (PepsiCo or other) for the 14.9 oz Irish beer can, see Notes in STEPS 3, 5, and 7 for special instructions.

Note: If you can't obtain the specific cans listed above don't worry. The stove may be made from just about any two 12 oz aluminum cans.

However, there are advantages to the suggested cans. A 12 oz PepsiCo can is preferred for the top section because the circular ridge on the bottom of a PepsiCo can is narrower than that of other brands and forms a circular groove on the inner surface that holds the inner wall of the stove snugly.

[Note from editor: I've never seen this. All 12-ounce (355 ml) aluminum drink cans are the same as far as I can tell.]

The 14.9 oz Irish beer cans listed above are favored for the bottom section of the stove because the diameter of these cans is slightly smaller than the diameter of a 12 oz can which fits snugly over a 14.9 oz can without having to cut slits, crease, or otherwise weaken either can. If a 12 oz can is used for the bottom section the stove will be slightly more difficult to make and will have a less finished look from the vertical beads of epoxy on it's exterior (see Fig. 17), but the stove will function just as well.

OPTIONAL SIMMER RING

Aluminum can, one of:

Note: The inner diameter of the raised rim on the top of a 24 oz Miller beer can is 62 mm (2 7/16 in). Other large cans with a top rim diameter of 58 to 62 mm (2 5/16 to 2 7/16 in) may perform as well, but all large cans do not have the same size top.

For metric / imperial converstions, see the

BackpackGearTest.org Conversion Utility.

STEP 1. MAKE THE BURNER HOLES

Summary. The top section of the stove is constructed in STEPS 1-3 from a 12 oz PepsiCo can. In STEP 1 a sewing needle with a shaft diameter of 0.6 mm (0.024 in) is used to make a circular ring of 32 evenly spaced holes outside and concentric with the circular ridge on the bottom of the PepsiCo can.

Figure 1

Details. Remove the pop-top tab from the top of the can and set the can upside down on a hard, flat surface such as a work bench or a cutting board placed on a table top.

Tip. To achieve evenly spaced burner holes, mark their location with a marking pen before punching the holes (Fig. 2).

Using a hose clamp, fasten the sewing needle to a rod with a diameter of about 13 mm (1/2 in) and a length of about 70 mm (2 3/4 in). The needle should be parallel to the long axis of the rod (i.e., straight, not crooked) with only 4 mm (3/16 in) of the needle extending past the end of the rod (Fig. 3). This lessens the likelihood that the needle will bend and break off. For the same reason, the edge of the hose clamp should be nearly flush with the end of the rod.

Figure 2

Note: The rod and hose clamp are not required, they just make the job easier. Two optional methods of making holes with a needle are described. Option 1, pierce a cork stopper with a needle so that the pointed end extends about 3 mm (1/8 in) beyond the cork. Position the needle where you want a hole and tap on the blunt end of the needle with a hammer. The cork prevents bending of the needle. To further prevent bending, you can trim the blunt end of the needle with wire cutters to within about 6 mm (1/4 in) of the cork. Option 2, simply grip the needle near the point with vice grips or needle nose pliers, position the needle where you want a hole, and pierce the aluminum can with hand pressure..

Tip. Use one or two new needles for each stove. New needles are sharp and pierce the aluminum better than dull, used needles.

Cautionary Note: Protect your eyes with safety glasses or goggles when making the burner holes.

Figure 3

Position the point of the needle where you want a hole, adjust the rod so that the needle is perpendicular to the surface at the hole, and rap gently on the end of the rod with a hammer or simply push the needle into the can with hand pressure. After the 32 holes are punched with the 4 mm (3/16 in) offset needle, go back over the holes with a needle offset 9 mm (3/8 in) past the end of the rod. Push the needle in for most, if not all, of its exposed length. If the needle shaft feels rough at any time during this process, smooth it with fine sandpaper (400 grit). The goal is for each hole to have the same diameter so that the flame will be uniform.

Tip. The burner holes are more easily made with a push pin than a sewing needle. For that reason and for safety, a push pin and a small hammer are the preferred tools of young hands. However, push pins shafts are thicker than needles, typically 1 mm (0.040 in) in diameter, thus they make a larger hole and the fuel doesn't burn as cleanly. If you use a push pin make 24 holes instead of 32.

STEP 2. FORM THE LARGE CENTRAL HOLE (Fig. 4)

Figure 4

Summary. Concentric with the circle of burner holes you made in STEP 1 is a raised circular ridge. Inside the ridge is a bowl-shaped area about 45 mm (1 3/4 in) in diameter. Use a utility knife to cut out the bowl at the base of the circular ridge, but leave the circular ridge and its sides intact. Round the rough edge of the hole with a half round file and smooth it with fine sand paper.

Details. To cut the large central hole with a utility knife, arm the utility knife with a keen (not dull) sharp point (not round point) blade. A dull blade may damage this section of the stove. Hold the can firmly, bottom side up on a hard, flat surface. Score the aluminum can at the base of the circular ridge all the way around its circumference (Fig. 5). On the first pass use very light pressure to obtain a smooth circle. After the first complete turn, continue the process 3-6 more times with light to moderate pressure (never heavy pressure) until the bowl-shaped area of the can pops out.

Figure 5

Tip. With a sharp blade and good technique there is no need to push the blade through the aluminum. Nevertheless, in difficult cases you may find it advantageous to push through the well scored circle with the tip of the blade making a 3 mm (1/8 in) long slit, or if necessary, several consecutive slits to form a longer slit. While making the last slit (the first could be the last), the bowl-shaped section will pop out or drop down with a tearing sound. If it drops down but doesn't pop out, rap in the center of the circle with the base of the utility knife handle, but don't rap so hard that you bend the can.

Shape the large central hole to the base of the circular ridge with a half round file (smooth cut). Smooth the edge of the hole with 320 to 500 grit sand paper.

Tip. Place the can bottom side up on a hard, flat surface and file vertically. Remove material right up to the base of the ridge. Then, use your fingers to gently bend the remaining thin aluminum edge up into the large central hole so that it can be filed off in the opposite direction (i.e., reverse the file).

Tip. When cutting, filing or sanding, hold the can high at the end to avoid putting a permanent dent in the weak side walls of the can particularly within 25 mm (1 in) of the burner holes. Exert downward pressure toward the opposite end, not inward pressure toward the center.

Tip. Save the cut out aluminum "bowl" for mixing epoxy.

STEP 3. CUT OUT THE TOP SECTION (Fig. 6)

Figure 6

Summary. Cut out the top section of the stove with a utility knife blade or scissors so that the finished height is 22 mm (7/8 in). The height of the top section is not as critical as the bottom section and inner wall. The suggested range is 20-24 mm (13/16-15/16 in). Use fine sand paper to prepare the interior surface of the sidewall for epoxy. Clean with warm water. If and only if the bottom section of the stove will be made from a 12 oz can, cut 8 vertical evenly spaced slits in the side wall to a depth of 3 mm (1/8 in) from the shoulder of the can. Burnish the slits.

Details. Two methods are given for cutting the aluminum can. Each works well, but practice on spare cans before cutting the real stove top.

Figure 7

To make an even cut with a sharp point utility knife blade, hold the blade horizontal and steady 22 mm (7/8 in) in height above a flat surface, such as a table top. The blade can be trapped in a hard cover book (Fig. 7) or fixed to a block of wood. A blade with a hole in the middle is easy to secure to the top of a block of wood with a screw and a brad or two. To hold the blade in a book, tape the blade to a stiff piece of paper or thin cardboard, insert the cardboard between the pages of the book, and close the cover. When scoring the can, push down firmly on the book with even pressure to lock the blade in space.

Figure 8

By block or by book, the point of the blade extends about 10 mm (3/8 in) past the edge. Place the PepsiCo can bottom down on a hard, flat surface. Bring the point of the blade in contact with the can and the side of the can in contact with the block or book. Rotate the cutting tool (wood block method) or rotate the can (book method) so that the blade scores the can (Fig. 7). Repeat for about 3 to 5 complete rotations until the can is well scored. Apply gently pressure to the side of the can so that you don't put a permanent crease in the can or pierce through the can with the blade.

When the can is well scored, take the utility knife and cut through the side of the can all the way around its circumference far enough above the score line that you don't dent the can below the score. A couple of centimeters (1 in) above the score line is usually sufficient. From the edge of the new cut, use scissors or a utility knife to cut toward the score at a 45 degree angle until within about 3 mm (1/8 in) of the score. Grab a corner where the last cut was started and tear the aluminum along the score all the way around the can. Tear the aluminum by pulling outward, i.e., away from the center of the can.

Alternatively, cut the can with strong scissors. First draw a line around the entire circumference of the can with a marking pen (Fig. 8). Keep the marker stationary while you rotate the can about its long axis with its bottom on a flat surface. To keep the marker stationary, use a piece of cardboard with a hole punched in it to insert the marker tip. Actually the cardboard should have two holes, one 22 mm (7/8 in) from a straight edge and one 28.5 mm (1 1/8 in) from a straight edge for the top and bottom sections, respectively.

Take the utility knife (including the handle) and cut through the side of the can all the way around its circumference far enough above the marked line that you don't dent the can below it. A couple of centimeters (1 in) above the line is usually sufficient. From the edge of the new cut, use scissors to cut toward the line at a low (acute) angle. Approach the line slowly. It may take 5 or more complete revolutions to finish the cut and the last revolutions may trim off 1 mm at a time.

Tip. The stove looks best if the height is consistent around the entire circumference. To check the height, place the stove top upside down on a flat surface and hold a ruler vertically next to the can. Rotate the can and check the height of the cut edge against the ruler.

Figure 9

Lightly sand the interior of the side wall of the top section with 320 to 500 grit sandpaper. This prepares the surface for J-B Weld (see STEP 6). You can also sand the cut edge of the top section, but if you care about stove cosmetics and you aren't going to cover the stove exterior with tape (see STEP 9) then don't sand the outer surface.

Clean metal particles and dried soda from the top section, especially that in the groove, with warm water from a faucet. A bottle brush or old toothbrush is helpful.

If you plan to use a 12 oz can for the bottom section instead of a 14.9 oz Irish beer can, cut vertical slits in the sides of the top section of the stove with scissors. The slits start from the cut edge of the top section and end 3 mm (1/8 in) from the shoulder (rounded edge) (Fig. 9). Make 8 slits evenly spaced around the circumference of the can. Burnish the slits with a hard, rounded object such as an old spoon, a coin, or the handle of a felt-tipped pen to close up the slit and smooth it. This is done by holding the top section sideways on a hard, flat surface so that the length of a slit contacts the flat surface, and rubbing the slit on the inside of the top section.

STEP 4. CUT OUT THE BOTTOM SECTION (Fig. 10)

Figure 10

Summary. The bottom section of the stove is made from a 14.9 oz can of Guinness Draught, Caffrey's Irish Ale, or Murphy's Irish Stout. Cut the bottom section 28.5 mm (1 1/8 in) in height. The height of the bottom section is important. It should be within the range of 27 to 30 mm (1 1/16 to 1 3/16 in) around the entire circumference. Use fine sand paper to prepare the upper third of the side wall exterior surface for epoxy. Clean with warm water.

Note: A 12 oz can (preferably one that matches the top section) may substitute for the 14.9 oz Irish beer can, but you must cut slits in the top section as described in the last paragraph of STEP 3.

Details. Cut the bottom section following either the utility knife blade or the scissors procedure of STEP 3 and the tips below.

Tip. Check the height with a ruler. Place the stove bottom right side up on a flat surface and hold a ruler vertically next to the can. Rotate the can and check the height of the cut edge against the ruler. Actually, I make my 14.9 oz Irish beer stove bottoms 30 mm (1 3/16 in) and my 12 oz stove bottoms 27 mm (1 1/16 in) tall.

Tip. If you are careful not to dent the unused portion of the aluminum can, you may use it to make the inner wall of the stove (STEP 5). Otherwise you will need an extra undented, generic aluminum can.

Lightly sand the cut edge of the bottom section and the upper 1/3 of the exterior surface of the side wall with 320 to 500 grit sandpaper. This facilitates stove assembly and bonding of J-B Weld, respectively. Clean the bottom section with warm water.

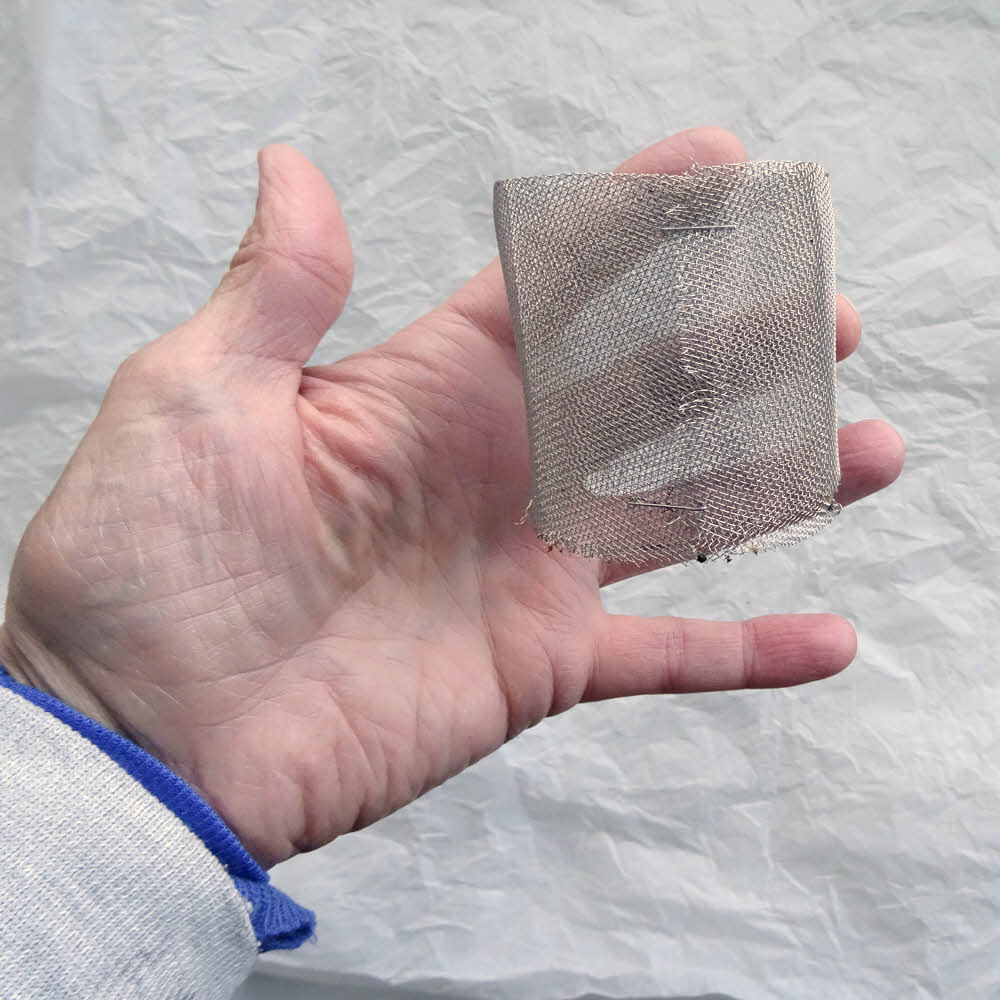

STEP 5. MAKE THE INNER WALL OF THE STOVE (Fig. 11)

Figure 11

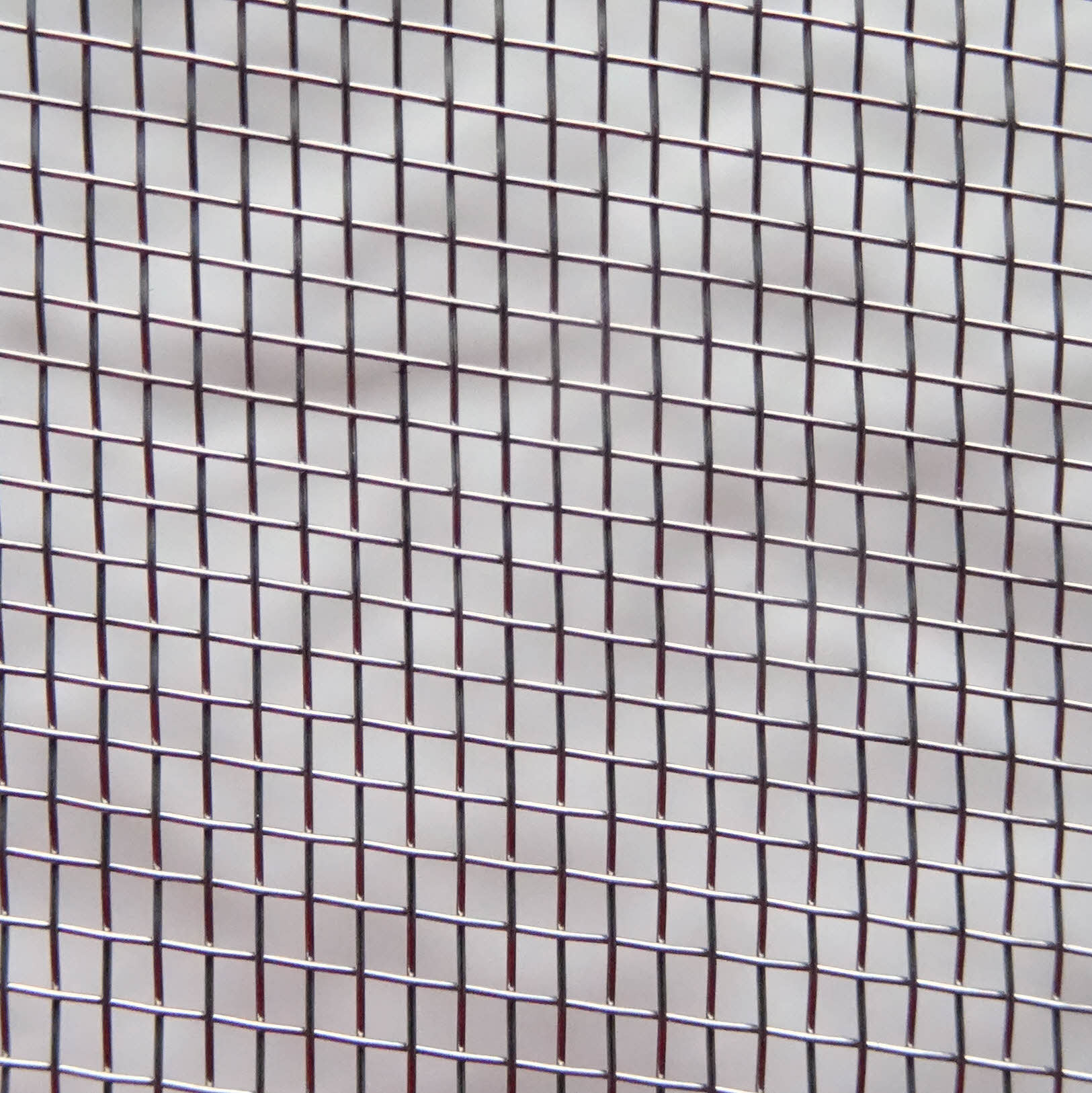

Summary. From the remainder of the Irish beer can (or a spare 12 oz can) fabricate a rectangular band 35 mm (1 3/8 in) wide and 180 mm (7 in) long (Fig. 12). The width of the rectangular band is important. The acceptable range is 34-36 mm (1 11/32-1 13/32 in). The length is less important. It can be 170-180 mm (6 11/16 to 7 1/16 in). Form 3 gaps along one of the long edges, each 2.5 mm (3/32 in) deep. The center gap is at the midpoint of the edge and the other two gaps are 50 mm (2 in) from it. Opposing slits, 150 mm apart, are optional and are explained in the Note at the end of STEP 5.

Note: If you use a 14.9 oz Murphy's Irish Stout can or any 12 oz can for the bottom section (STEP 4), make the rectangle 38 mm (1 1/2 in) wide and the 3 gaps 5 mm (3/16 in) deep.

Overlap the short sides of the rectangular band to form a cylinder that fits snugly into the circular groove of the top section. Use tape and/or Krazy glue on the outside surface to temporarily bond the cylinder together. Follow with a thin bead of J-B Weld over the external tag end of the band to permanently cement the cylinder.

Details. Use a utility knife to cut off the remaining end (the top) of the Irish beer can, or the top and bottom of a generic can, about 2.5 cm (1 in) from the end(s) so that you have a cylinder with ragged edges. With scissors, cut vertically straight across the cylinder to form a ragged rectangle. Lay the aluminum down on a cutting board and place a straightedge on top parallel to a long side. Trim off one ragged long side with the utility knife using the straightedge as a guide.

Figure 12

Tip. When cutting the aluminum with the straightedge and utility knife, score the aluminum lightly and repeat several times. Hold the straightedge firmly in place and bend the aluminum at the score upright 60 to 90 degrees and then back down. Repeat this bending process until the aluminum breaks off evenly at the score

Measure 35 mm (1 3/8 in) from the new smooth edge and repeat the cut to form the opposite long side. The long sides should be as parallel as possible. You now have a long rectangle. Call it a band. Trim one of the short sides of the band perpendicular to the long sides. Cut the other short side 180 mm (7 in) from its opposing side.

Figure 13

To allow the alcohol fuel to flow from the middle of the stove to the space between the walls, make three gaps along one of the long edges of the band. One gap is at the midpoint of a long edge and the other two gaps are 50 mm (2 in) out from the midpoint. Mark their location with a marking pen. Form arch-shaped gaps by using a hole punch set in from the edge about 40% of its diameter or 2.5 mm (3/32 in) deep.

Alternatively, if you don't have a hole punch, make the gaps with scissors or a utility knife. To form a rectangular gap, cut two slits perpendicular to the long edge of the aluminum band 2-3 mm deep and 3 mm apart. Bend the aluminum between the slits flat against the painted side of the band.

Figure 14

Wipe the surface of all three stove parts with tissue paper soaked in denatured alcohol. Denatured alcohol removes marking pen ink as well as cleans the surface for bonding of J-B Weld.

Convert the inner wall band into a cylinder as follows. Pull off a 2 cm (3/4 in) piece of masking tape and set it aside. Place the top section of the stove upside down on a flat surface. Overlap the ends of the band about 30 mm (1 3/16 in) to form a cylinder. Seat the cylinder into the circular groove of the top section. Tighten the cylinder, making sure it remains fully seated in the groove. Holding the area where the ends of the cylinder overlap, carefully remove the cylinder without changing its diameter. Make sure the overlapped edges of the cylinder are even and place the piece of masking tape on the outside of the cylinder across the tag (free) end (Fig. 13).

Check the diameter of the cylinder as follows. Reinsert the cylinder, overlapped area first, into the circular groove. The cylinder should fit snugly in the groove but not tightly. In other words, it should take a little force, say 0.5-1 kg (1-2 lb), to push the cylinder into the groove but it should not take so much force that the cylinder goes out of round. Adjust the diameter of the cylinder until it is correct. If the cylinder is close to the right diameter, small adjustments of 0.5-1 mm make a difference. A snug cylinder makes stove assembly (STEP 6) easier and properly directs vaporized fuel out the burner holes. A cylinder that is too tight may buckle during stove assembly. When you are satisfied with the cylinder size, glue down the tag end on the outside of the cylinder with a drop or two of Krazy glue.

Tip. Place two small pieces of masking tape across the top and bottom edges of the cylinder in the middle of the overlap. Remove the original piece of tape from the tag end on the outside surface of the cylinder and apply Krazy glue under the tag end.

After the Krazy glue bonds (10-15 sec), remove the tape. To prepare the surface for J-B Weld, lightly sand the tag end on the outside of the cylinder and a few mm on either side of it. Retest the cylinder diameter by fitting it into the circular groove of the stove top so that the edge WITHOUT the gaps is in the groove. If it fits snugly, leave it in the groove. If the cylinder fits loosely see STEP 7 for how to correct a loose fit. If the fit is too tight break the Krazy glue bond with heat and readjust the cylinder diameter, or make a new cylinder.

Use a wooden match stick or toothpick to apply a thin bead of J-B Weld about 3 mm (1/8 in) wide covering the edge of the tag end on the outside surface of the cylinder. Allow the J-B Weld 5 hr or more to partially cure before proceeding with stove assembly (STEP 6), or immediately proceed with stove assembly being careful not to touch the uncured epoxy.

Note. J-B Weld is necessary because the heat produced during stove operation loosens the Krazy glue bond and the cylinder would otherwise unravel. If you choose to let the epoxy cure before proceeding you might as well apply the epoxy with the cylinder unattached to the top section. It's easier that way.

Note. In the first version of the Pepsi Stove instructions, the cylinder was held together with two interlocking slits rather than J-B Weld. This design is stronger than the one above, though more difficult to execute because precise slit distance is critical to obtain a snug fit. [See STEP 7 for how to seal a loose fit.] Slit instructions are repeated here for those that prefer them. Measure 15 mm (5/8 in) in from one of the short sides of the rectangle and cut a slit into one of the long sides of the rectangle. Slit depth is slightly more than half the length of a short side, or 18 mm (3/4 in) for a 35 mm (1 3/8 in) wide band. Make the slit as perpendicular to the long sides as possible.

Measure 150 mm (5 29/32 in) parallel to the long sides and make the second slit in the edge of the opposite long side. Interlock the two slits of the long rectangle to make a cylinder so that the tag ends are outside the cylinder (Fig. 14). Tape down one of the tag ends with a small piece of masking tape, making sure the edges of the tag end are even with the edges of the cylinder. Glue the untaped tag end to the outside of the cylinder with a drop or two of Krazy glue, making sure the edges of this tag end are even with the edges of the cylinder. Remove the tape and glue down the free tag end. Seal the interlocking slit and affix the two tag ends with three parallel thin beads of J-B Weld on the outside surface of the cylinder. Allow the J-B Weld 5 hr or more to partially cure before proceeding with stove assembly (STEP 6), or immediately proceed with stove assembly being careful not to touch the uncured epoxy.

STEP 6. ASSEMBLE THE STOVE (Fig. 15)

Figure 15

Summary. Fit the gapless edge of the inner wall into the circular groove of the top section. Slide the bottom section inside the top section. When the bottom section barely fits inside the top section, apply a thick bead of J-B Weld around the entire circumference of the bottom section just below the edge of the top section. Compress the sections together until the inner wall is tightly trapped between the top and bottom sections. Wipe off the excess epoxy. If the top section has slits, install rubber bands to compress the slit sides. Invert the stove and put a weight on top. Cure for at least 5 hr.

Details. Before assembling the stove, make a rectangular shim from aluminum can scraps to help ease the top section over the bottom section. From the side of an aluminum can cut out a rectangle about 25 x 65 mm (1 x 2 1/2 in). Round off the corners of the rectangle and lightly sand the edges. The shim should be smooth and undented particularly along its edges. Save the shim for ensuing stoves.

Figure 16A

If you haven't done so already, insert the cylindrical inner wall into the circular groove of the stove top so that the edge without the gaps is in the groove.

Place the top section (with the inner wall held in its groove with friction) over the bottom section and angle the top section so that one part of its edge overlaps the edge of the bottom section by about 3 mm (1/8 in). Fix the two sections together at that point with a short piece of tape, about 40 mm (1 1/2 in) long (Fig. 16A). On the side of the stove opposite the tape insert the shim between the edges of the top and bottom sections (Fig. 16B). Move the shim along the junction of the edges right to left (or left to right) as needed to ease the top section over the bottom section.

Figure 16B

When the edge of the top section barely overlaps the edge of the bottom section around the entire circumference, remove the shim and the tape and press the two sections together slightly so that they overlap by 6 mm (1/4 in) or less. Apply a thick, continuous bead of J-B Weld about 10 mm (3/8 in) wide around the entire circumference of the bottom section just below the edge of the top section. Press the top and bottom sections together slowly until the inner cylinder is held firmly between the top and bottom sections.

During this compression process, make sure the cylindrical inner wall is seated in the circular groove of the top section and keep the straight side walls of the two sections as parallel as possible. As long as you do, the stove should easily withstand 2-4 kg (5-10 lb) of vertical force. When the inner wall is flush against the bottom of the bottom section and the stove does not compress any further with moderate pressure, stop. Don't compress the stove with so much force that you bend the inner wall. The stove should be 40 mm (1 9/16 in) in height.

Note. The circular groove on the bottom of a Guinness or Caffrey's can has a larger diameter than the circular groove of a PepsiCo can, thus the cylindrical inner wall won't fit into the groove of a Caffrey's or Guinness bottom stove section. This is not a problem. Ignore it. On the other hand, the circular groove of the Murphy's can is approximately the same diameter as the PepsiCo can, thus the cylindrical inner wall fits into the circular groove of the Murphy's can.

Thoroughly wipe off the excess epoxy with paper towels, facial tissue, or toilet paper. Keep the epoxy off your fingers so that you don't transfer it to the burner holes.

Note: If the top section has slits be careful not to bend them when wiping off the epoxy. Once the excess epoxy is cleaned up, put several rubber bands around the stove to clamp the slit sides of the top section against the outside of the bottom section.

Invert the stove, put a weight on top (e.g., can of soup) and let the epoxy cure for at least 5 hr before proceeding to STEP 7 or at least 15 hr before proceeding to STEP 8.

STEP 7. SEAL THE TOP SECTION (Fig. 17)

Figure 17

Summary. Use J-B Weld to seal the three potential sites for flame leaks: 1) the junction of the top edge of the inner wall and the circular groove, 2) under the circular edge of the top section on the side wall of the stove, and 3) the 8 vertical slits in the top section. Skip STEP 7 if the inner wall fits snugly in the groove of the top section and you are not a perfectionist, if the top and bottom sections are undented and generously bonded with J-B Weld, and if the top section does not have slits.

Details. If the inner wall fit loosely in the circular groove of the top section or you are inescapably meticulous, seal the gap between the top of the inner wall and the circular groove. Use a wooden match stick or toothpick to scrape J-B Weld into the space between the top of the inner cylinder and the lip of the circular groove. Use Q-tips to force the J-B Weld into the gap, smooth out the epoxy, and remove most of the excess epoxy. Use paper towels, facial tissue, or toilet paper to thoroughly wipe off excess J-B Weld from the inner cylinder. If further sealing is planned, immediately proceed to the next paragraph. Otherwise, let the epoxy cure for at least 15 hr before using the stove.

If the top and bottom sections are dented and/or J-B Weld was used sparingly to bond these two sections together, then there may be an air gap for a flame leak. Put a bead of J-B Weld over the circular edge of the top section on the side wall of the stove, and try to force epoxy under the edge with a Q-tip. Wipe off the excess epoxy. Immediately proceed to the next paragraph if your stove has slits in the top section. Otherwise, let the epoxy cure for at least 15 hr before using the stove.

If you cut slits in the top section of the stove, seal each slit with a thin bead of J-B Weld about 2 mm (3/32 in) wide. Use a wooden match stick or toothpick to apply the epoxy. Let the epoxy cure for at least 15 hr before using the stove.

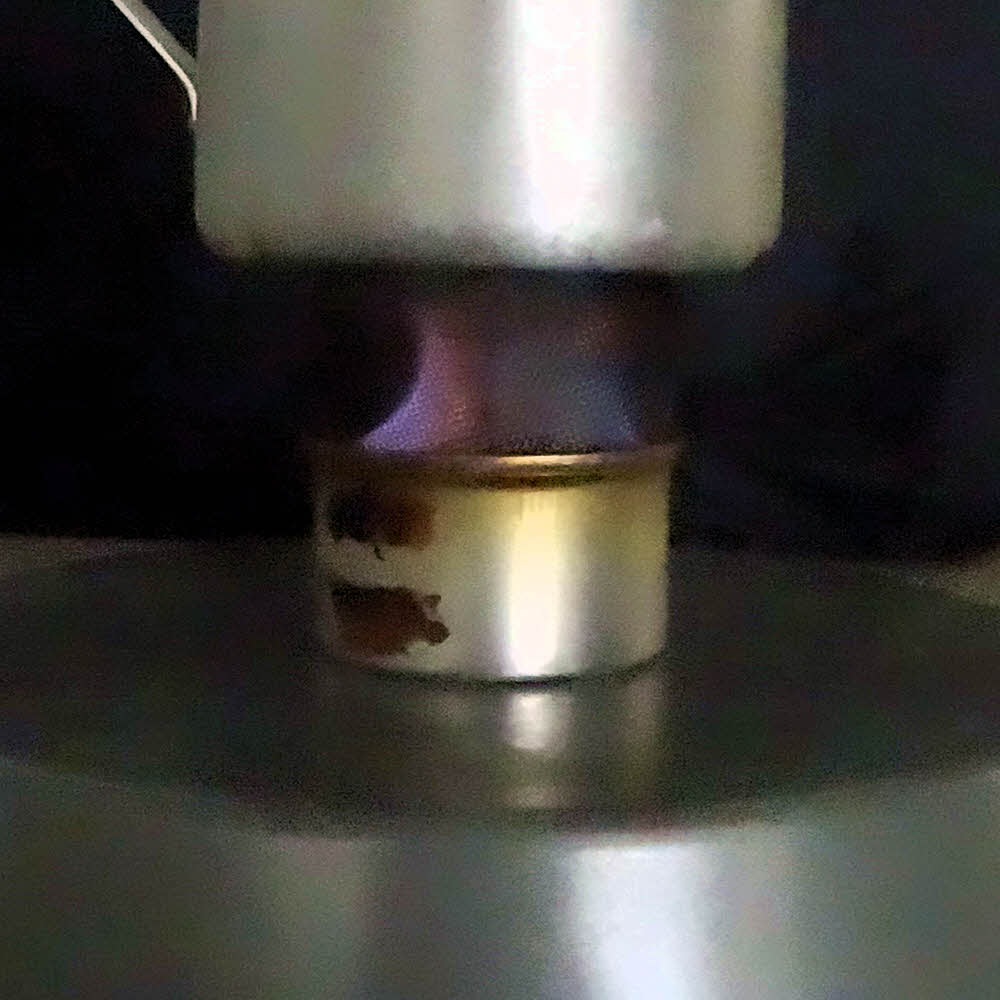

STEP 8. TEST THE STOVE (Fig. 18)

Figure 18

Summary. Test the stove for proper operation and flame leaks.

Cautionary Note: Perform this test is subdued light. An alcohol flame is nearly invisible in bright light. When the flame burns out, let the stove cool for a couple of minutes before touching it with bare fingers.

Details. Put 250 ml (1 cup) of water in a cooking pot and set it aside. Set the stove on a heat resistant surface such as a dinner plate or pie tin. Pour about 15 ml (1 T or 0.5 fl oz) of denatured alcohol or methanol down the large central hole of the stove and light it. It takes about a minute for this volume of room temperature alcohol to heat up, vaporize, and achieve an even burn out the burner holes. Hold the pot about 2.5 cm (1 in) above the flame. You should observe an even, circular pattern of (mostly) blue flame coming out of the small burner holes.

If the flame doesn't come out of the burner holes you likely have a problem with the inner wall. Either it is too loose or the gaps are blocked off. If the inner wall is too loose seal it at the top with J-B Weld (see STEP 7). If you can't rotate the inner wall with your fingers it is not too loose. If the gaps are blocked off, punch or cut holes at the base of the inner wall. If you can see the gaps they aren't blocked off. A predominantly orange flame indicates poor fuel quality or poor oxygenation of vaporized fuel.

Note: Without a pot over the stove, it appears to the novice that the flame burns excessively high. Further, it may appear that the flame comes largely out of the central hole, but that is an optical illusion unless it happens with the pot test.

Put the pot down and check for flame leaks at the junction between the top and bottom sections of the stove and at the slits in the top section (if there are any). Rotate the plate to check the entire circumference of the stove. If there is a flame leak seal it with J-B Weld. Let the epoxy cure for at least 15 hours before retesting the stove.

STEP 9 (Extremely Optional). FINISHING TOUCHES (Fig. 19)

Figure 19

Summary. Some artisans may want to befuddle their buddies and beautify their burner by disguising the graphics and junction of the top and bottom sections with heat resistant tape.

Details. Pull 30 cm (12 in) of 3M High Temperature Flue Tape off the roll and cut the 1 1/2 in wide tape in half lengthwise. This produces two pieces of tape about 20 x 300 mm (3/4 x 12 in), which is enough for two stoves. Trim a couple of centimeters (1 in) from each end to have a clean, wrinkle-free piece. Center the tape on the side wall of the stove and tape over the junction of the top and bottom sections. As you install the tape, burnish it by rubbing with your thumb, but don't push too hard and put a dent in the stove. The tape can be removed at any time with no damage to the stove and the tape residue cleaned off with denatured alcohol or acetone.

Alternatively, install heat resistant, self-adhering silicone tape. One brand is Tommy Tape. It comes in a variety of widths, but be aware that Tommy Tape should be stretched during installation so it becomes 25% narrower than it is on the roll. Consequently 3/4 in wide tape becomes 9/16 in wide installed and 1 in wide tape becomes 3/4 in wide installed. Tommy Tape comes in a variety of thicknesses and two cross-section shapes. I recommend the 20 mil thickness and rectangular cross-section. The regular colors are dull but vibrant colors will soon be offered. If you are lucky you can find the tape in a local retail store. If not, order it from

tommytape.com.

If you are hesitant to take the plunge for a 10 or 36 ft roll, they offer a 3 ft evaluation roll for $1.95 (including shipping), but be warned, the tape is tricky to work with because it is self-adhering and you may waste 3 ft just learning how to handle it. One downside of this tape is that dirt and sand tend to stick to the tape like they do to a silnylon tarp. Cut 30 cm (12 in) off the roll, which should be enough for 2+ turns around the stove. Trim the corners off both ends. Center the starting end on the side wall of the stove and hold it there tightly as you stretch and wrap the tape around the stove. The tape sticks to itself but it doesn't stick to the stove, thus you can roll the tape off if you want to remove it.

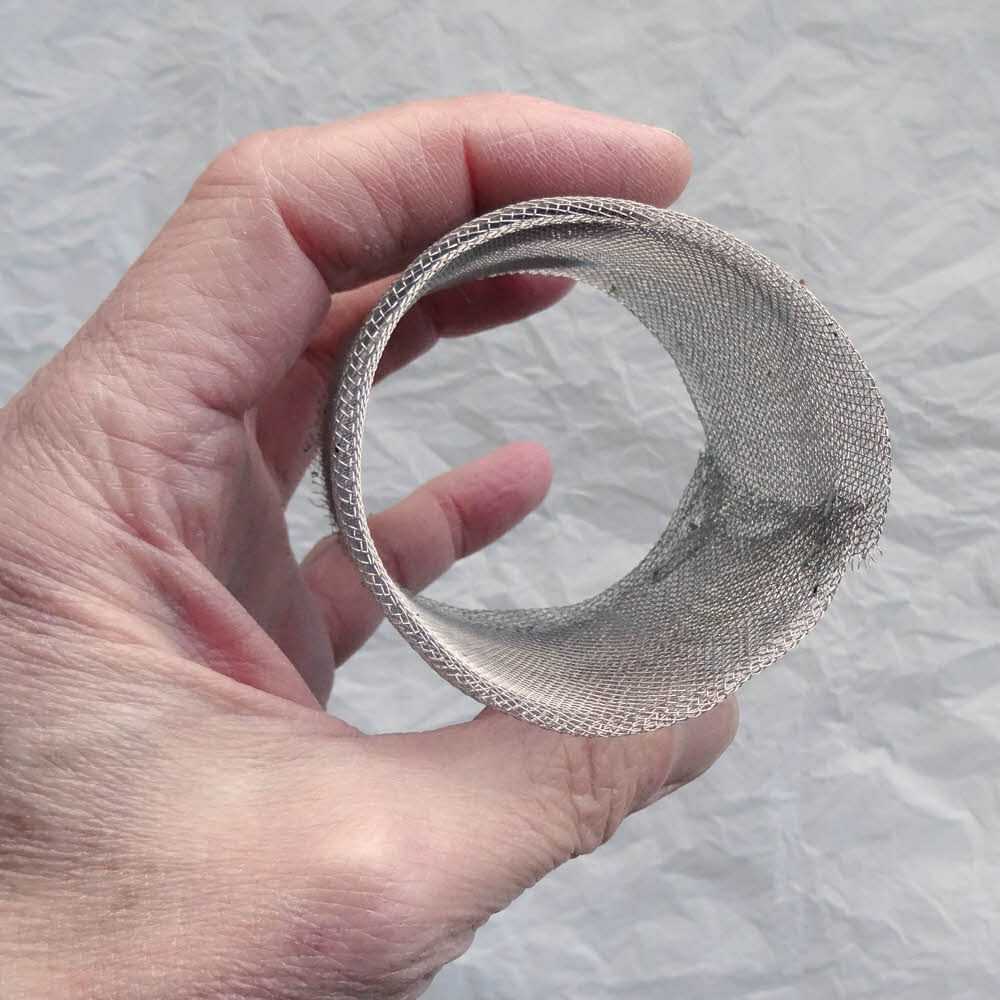

STEP 10 (Optional). MAKE A SIMMER RING (Fig. 20)

Figure 20

Summary. The simmer ring is made from the top of a 24 oz Miller beer can. Enlarge the pop top hole with a file. Tear the side wall of the can away from the top. Press (or hammer) the top surface of the can top downward against a flat surface to form a cake pan shaped simmer ring.

Details. Wiggle the pop top back and forth until it falls off. Enlarge the hole with a half round and/or a round file, and smooth the edge of the hole with fine sandpape.

Note: You may find with experience that you want a larger opening than the pop top makes. The prospective simmer ring pictured in Fig. 20 has a slightly enlarged hole. It is easier to enlarge the opening before releasing the top from the can.

Release the flat can top from the rest of the can by cutting the side wall of the can all the way around the perimeter about 2-3 cm from the top. From the cut edge of the side wall, cut a slit down to within a few mm of the flat can top. Tear the side wall away from the top, which resembles a miniature pie plate. If the flap that covered the hole is still attached to the back, pull it off. Do not bend the top while removing the side wall material.

Place the can top right side up (rim up) on a flat, hard surface. Pound down, or better, press down the horizontal portion of the can top until it is flat against the flat, hard surface. Do not bend the circular rim portion of the can top or its short horizontal sides. That's all. You now have a simmer ring.

Tip. A solid cylinder (metal, plastic, or wood) with parallel faces helps in this procedure, especially if the diameter of this cylindrical tool is slightly smaller than the diameter of the can top rim so that the cylinder fits snugly inside the can top.

The simmer ring is typically used after the dinner has come to a boil. Place the simmer ring upside down on top of the large central hole of the stove. The outside edge (or rim) of the ring should cover the burner holes which forces the alcohol flame to come out the hole of the simmer ring. It takes a minute or so for the flame to come to a new low flame equilibrium. If you want to switch back to high heat, then simply remove the simmer ring. If you want to extinguish the flame, it is easier to blow out if the stove with the simmer ring in place. Let the stove cool and pour any remaining fuel back into the fuel bottle.

Be careful. The simmer ring gets too hot to touch with bare fingers. You can place or remove the simmer ring with multi-tool pliers, alligator clips, a spork, or a stick. Alternatively, you can install a mini handle made out of lightweight material attached with J-B Weld or a rivet.

Note: Set up the stove in an area protected from the wind and use a windscreen. This is especially important for this simmer ring design.

STEP 11. MAKE A POT STAND AND WINDSCREEN

Instructions for pot stands and windscreens are already well described on the internet:

Roy Robinson's Cat Stove.